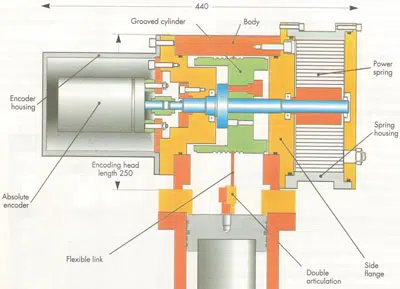

This equipment, mounted at the end of a cylinder, provides extremely accurate and reliable information on the position of the cylinder’s rod.

Operating principle: A link fixed in the axis of the cylinder piston provides sensing as it moves.

This flexible link rotates the grooved drum and the cross shaft to which it is flanged. Its tension, which is practically constant, is controlled by a spiral spring, known as the power spring.

Thanks to its double articulation, the flexible link remains parallel to the longitudinal axis of the cylinder.

Finally, the transverse shaft rotates the absolute encoder via a coupling.

The programmable absolute encoder signal is processed by an electronic control system.

MEASURE TO CONTROL

The power of hydraulics is now matched by the precision of measurement.

The position indicators are the only ones to:

- Ensure perfect synchronization between two or more cylinders of different cross-sections

- Adaptable to all types of cylinder Guard

- Deliver a Gray code signal recognized by all ECUs

- Programmable to an accuracy of 1/10 mm

- Covering strokes up to 15 m

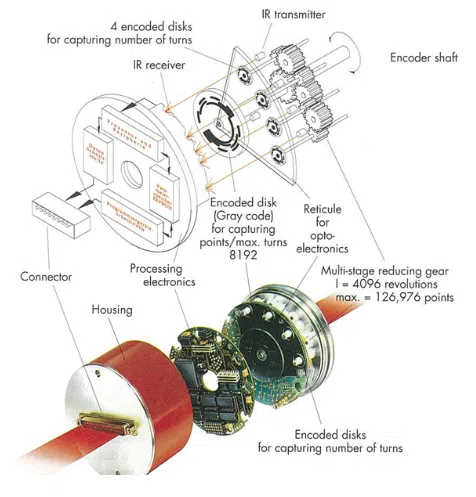

T + R ELECTRONIC ABSOLUTE ROTARY ENCODER

Principle: The measuring principle of absolute rotary encoders is based on the optical reading of a plastic or glass disc, which rotates with the axis.

An unambiguous code, Code Gray, is engraved on several concentric tracks, the number of which depends on the resolution required.

Each track is assigned an optoelectronic barrier, so each angular position generates a unique combination that corresponds to the angular position of the drive shaft.

In principle, the code engraved on the disk can be compared to a non-volatile memory. This enables the absolute value of the shaft position to be obtained instantaneously on power-up, thus avoiding the need for a reference.

FIELD OF APPLICATION:

With two types of sensor, we cover all cylinder strokes from 0 to 15m in length, operated at pressures from 0 to 350 bar.

The position sensor can be fitted either:

- Workshop work on new equipment

- On-site for older equipment requiring refurbishment

These sensors are a welcome replacement for the old external indicators, which drive screw-and-nut rotary position selectors whose mechanical fingers tilt the electrical contacts.

Connections between moving parts and control panels become purely electrical and can reach over 1000m.

THE VARIOUS MECHANICAL ADAPTATIONS

Two models are currently available:

- A type 82 sensor for cylinders with strokes from 0 to 8.5 m.

- A type 15 sensor for cylinders with strokes from 0 to 15 m.

For these two types of sensor, there are two possible configurations.

An intermediate element between the cylinder body and the position sensor is always an option for mounting on older, in-service equipment.